Projects fit to your objectives using consultancy, partnerships, and flexible business models.

Borehole seismic and beyond

Published: 03/23/2022

Borehole seismic and beyond

Published: 03/23/2022

Borehole seismic data collected during and after the drilling of exploration and appraisal wells delivers valuable information for reservoir characterization. Combined with surface seismic data, borehole seismic surveys can help calibrate results and improve predictions, as well as characterize specific features at reservoir scale.

SLB recently introduced Optiq Seismic fiber-optic borehole seismic solution, an innovative approach to conventional borehole seismic acquisition and a member of the growing SLB Transition Technologies portfolio that enables measurable environmental-impact reductions while simultaneously helping customers achieve high performance, sustainably. Fiber Optics Product Champion Nick Fundytus discusses how this new technology leverages the power of light to significantly improve oilfield operations, as well as other applications, such as carbon capture and storage (CCS) projects.

What are challenges with conventional borehole seismic acquisition, and how does Optiq Seismic solution improve operations?

Traditional borehole seismic acquisition relies on discrete geophones set at predetermined points downhole. This method requires a time-consuming rig-up and rig-down process and is not combinable with other wireline services, typically resulting in a minimum of 12 hours of rig time depending on the acquisition objectives. Seismic services are also often omitted from the data acquisition program when there are concerns about borehole stability, resulting in low data assurance.

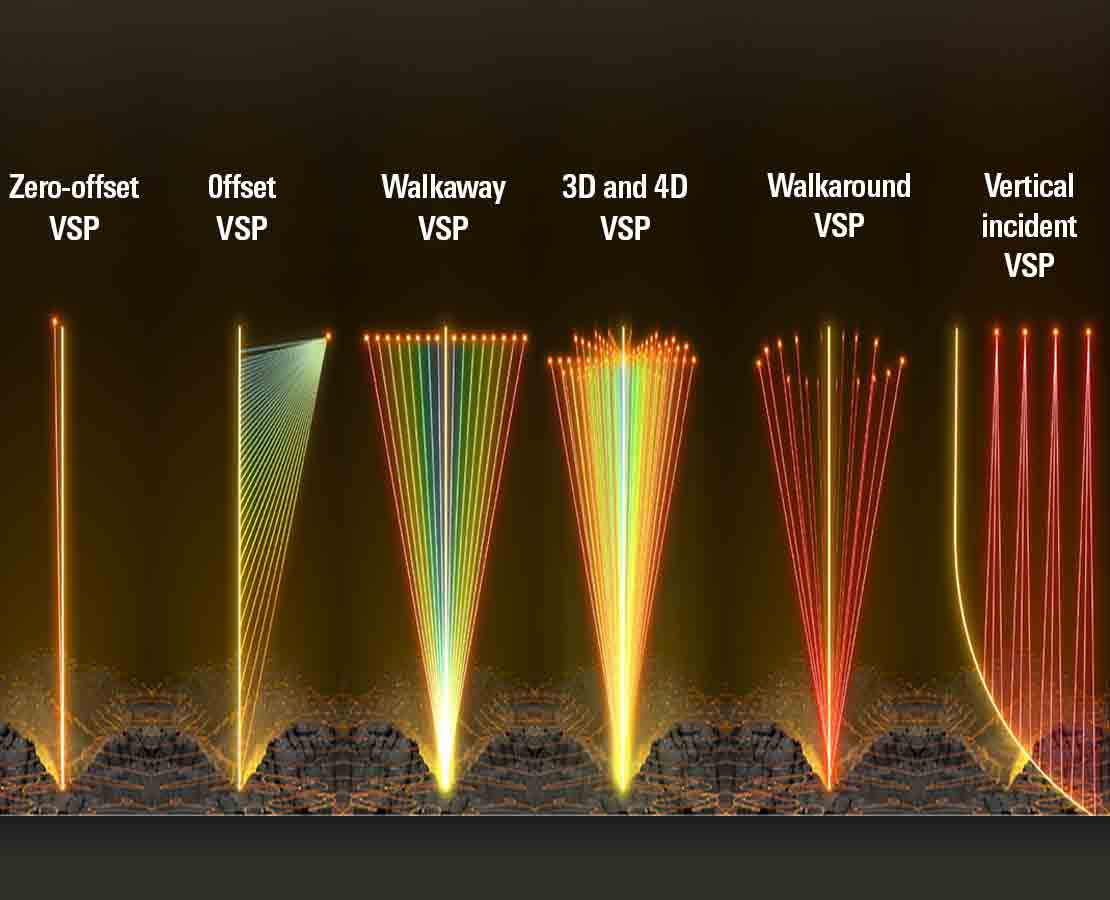

Optiq Seismic solution significantly changes conventional borehole seismic acquisition by using fiber-optic strands built into the conveyance—standard wireline, slickline, or coiled tubing—or permanently clamped to the tubing or casing. These strands act as the sensing element. This eliminates the need for downhole geophone arrays, the repetition of source points, and time-consuming rig-up and -down. The fiber enables continuous, real-time measurements captured along the entire length of the strand for asset-light operations, reducing stuck tool and fishing risks. It delivers rich data in a fraction of the time with up to 99% higher efficiency and reduced carbon footprint. This new solution acquires zero-offset, offset, walkaway, 3D and 4D, walkaround, and vertical incidence vertical seismic profiles (VSPs) in minutes compared with hours or days using the conventional approach. It also drastically reduces the number of seismic shots required compared with the geophone method. In offshore applications, this significantly minimizes impact to marine mammals that can be associated with seismic operations.

What makes Optiq Seismic solution unique from third-party tools?

The large volume of data produced with fiber optics can be a challenge to manage, often resulting in long processing times and requiring fiber optics expertise to interpret before making decisions. Optiq Seismic solution uses enhanced AI to improve processing time by up to 18× compared with industry benchmarks. In addition, the solution provides more than just measurements; it gives you end-to-end workflows—from planning, modeling, execution, to processing—for real-time decision making, so you can proactively maximize your returns. For example, in the planning phase, digital tools enable presurvey modeling to optimize data quality, and during the job execution phase, advanced edge processing enhances data QC and enables real-time alerts to eliminate the need to transmit gigabytes of data from the wellsite. And the ability to make adjustments in real time can be used as part of a long-term surveillance strategy.

What options are available for deploying the fiber in the well?

Optiq Seismic solution is the industry’s only deployment-agnostic fiber-optic borehole seismic solution. This means it can be deployed in any well in a way that suits your objectives. You can temporarily deploy it using our innovative fiber-optic wireline, slickline, or coiled tubing conveyances or permanently clamp it to production tubing or cement it behind casing.

This gives you operational flexibility based on your objectives while making every logging run an opportunity for borehole seismic data acquisition to significantly improve the efficiency of your operations. No longer is time required for rigging up and down and a dedicated seismic run, because the solution records seismic data either in conjunction with other services or on its own. This new ability to acquire data on any wireline, slickline, or coiled tubing descent eliminates the likelihood of canceling the borehole seismic acquisition due to time constraints or borehole stability concerns. In addition, it ensures that the well tie with surface seismic data can be performed and reservoir properties are delineated.

For temporary deployment, Optiq TuffLINE torque-balanced fiber-optic wireline conveyance has an industry-leading 18,000-lbf maximum safe working load and acquires high-resolution VSPs in any exploration and appraisal environment, including deep water. Another industry first is VSP acquisition during any production services run using Optiq StreamLINE polymer-locked fiber-optic wireline conveyance.

What are the benefits of installing fiber optics permanently in the well?

Permanent fiber installations enable you to integrate borehole seismic measurement with your completions to acquire 3D or 4D VSPs without deferring any production, thus saving time and costs. And with a better understanding of your reservoir, you can optimize positioning for future development wells and your completion strategy, as well as potentially reduce the number of required wells to further decarbonize full field development.

For example, Optiq Seismic solution was deployed for an operator in the Gulf of Mexico to better understand reservoir compartmentalization and improve well positioning. A hybrid fiber-optic and electrical cable was permanently installed along the production tubing as part of the completion string in four wells. This enabled simultaneously recording a 3D VSP in all four wells while the wells were still in production. Whereas the conventional downhole geophone method would have taken 100 days with deferred production, Optiq Seismic solution recorded the 3D VSPs within 12 days without any deferred production. It completely avoided intervening in the wells while saving ~7,500 metric tons of CO2e. The operator then used a denoising workflow to filter out production noise and obtain high-resolution images of the subsurface in less than 5 months from the start of the acquisition.

Read full case study: Fiber Optics Simultaneously Records 3D VSPs in Four Wells, Reducing Acquisition Time by 88 Days

You can also use permanent fiber installations for long-term surveillance of production and well integrity, as well as applications such as injection and containment monitoring to improve decision making.

How can Optiq Seismic solution be leveraged in other applications, such as CCS projects?

Schlumberger has been involved in CCS projects for more than 30 years, and now permanently installed fiber optics enables you to better optimize these operations to meet your CCS objectives while satisfying regulatory requirements. In addition to the measurements acquired using the fiber, Optiq Seismic solution gives you end-to-end workflows to enable real-time adjustments. Whereas the conventional geophone method only provided VSP data and microseismic monitoring, Optiq Seismic solution workflows deliver much more. They give you the unique ability to monitor pressure, injectivity performance across the injection zone, injection rate, storage volume, well integrity, and containment, as well as quickly react and make changes downhole as needed to maximize your returns. This fits into a comprehensive, long-term surveillance strategy using 3D and 4D seismic surveys and is also a more economical solution than the geophone method for scaling your CCS project.